Concrete is everywhere. From sidewalks and driveways to towering skyscrapers, this material is the backbone of modern construction. Yet, despite its ubiquity, many people still ask a simple but important question: What is concrete made of?

If you’ve ever wondered what goes into this sturdy, gray mixture, you’re not alone. Beginners, DIY enthusiasts, and even curious homeowners often want to understand the basics. In this guide, we’ll break down the ingredients, clear up common misconceptions, and explore the different types of concrete used around the world. By the end, you’ll not only know what concrete is made of, but also why it matters.

And if you’re looking for a reliable digital resource, Concrete Verse is here to help. With practical guides, tools like our Concrete Calculator and Concrete Slab Calculator, and easy‑to‑follow tips, we make concrete knowledge accessible to everyone.

What Is Concrete Made Of? The Essential Guide for Beginners

At its core, concrete is a mixture of four main components: cement, water, aggregates, and admixtures. Think of it like baking a cake. Cement is the flour, water is the liquid that binds it, aggregates are the sugar and eggs that give it bulk, and admixtures are the flavorings that tweak the recipe.

When cement and water combine, they form a paste. This paste coats the aggregates—sand, gravel, or crushed stone—and hardens over time. The result is a rock‑like material that can withstand enormous pressure and last for decades.

So, when someone asks “What is concrete made of?”, the answer is simple: it’s a carefully balanced recipe of cement, water, aggregates, and sometimes additives. But the magic lies in how these ingredients interact.

What Are the Main Ingredients of Concrete?

Let’s break down the recipe in more detail:

- Cement: This is the binding agent. Portland cement is the most common type used worldwide. It reacts chemically with water to form a hard paste.

- Water: Without water, cement can’t react. The amount of water used is critical—too much weakens the concrete, too little makes it hard to work with.

- Aggregates: These are the fillers that give concrete its bulk and strength. Fine aggregates (like sand) and coarse aggregates (like gravel or crushed stone) make up about 60–75% of the mix.

- Admixtures: These are optional chemicals added to improve performance. For example, some admixtures speed up curing, while others make concrete more resistant to freezing temperatures.

Each ingredient plays a role. The balance between them determines whether the concrete will be strong enough for a skyscraper or flexible enough for a decorative patio.

Is Concrete Just Dried Cement?

This is one of the most common misconceptions. Many people think concrete is simply cement that has dried. But that’s not true.

Cement is only one ingredient in concrete. On its own, cement is brittle and not very useful. Concrete, on the other hand, is a composite material. When cement reacts with water, it forms a paste that binds aggregates together. That’s what gives concrete its strength and durability.

So, saying concrete is “dried cement” is like saying a cake is just flour. Cement is essential, but it’s only part of the story.

What’s the Difference Between Cement and Concrete?

Here’s a quick comparison to clear things up:

| Aspect | Cement | Concrete |

| Definition | A fine powder made of limestone, clay, and other minerals | A mixture of cement, water, aggregates, and admixtures |

| Form | Powder | Solid, rock‑like material |

| Use | Ingredient in concrete and mortar | Used in construction for structures, pavements, bridges |

| Strength | Brittle on its own | Strong and versatile |

In short: cement is an ingredient, concrete is the finished product. Without cement, there’s no concrete. But cement alone can’t do the job.

What Is Poor Quality Concrete?

Not all concrete is created equal. Poor quality concrete can lead to cracks, structural failures, and costly repairs. But what makes concrete “poor quality”?

- Incorrect mix ratios: Too much water or too little cement weakens the structure.

- Low‑quality materials: Using dirty aggregates or impure water can compromise strength.

- Improper curing: Concrete needs time to harden properly. If it dries too quickly, it becomes brittle.

- Environmental exposure: Freeze‑thaw cycles, chemical exposure, or salt can damage concrete if it’s not designed to withstand them.

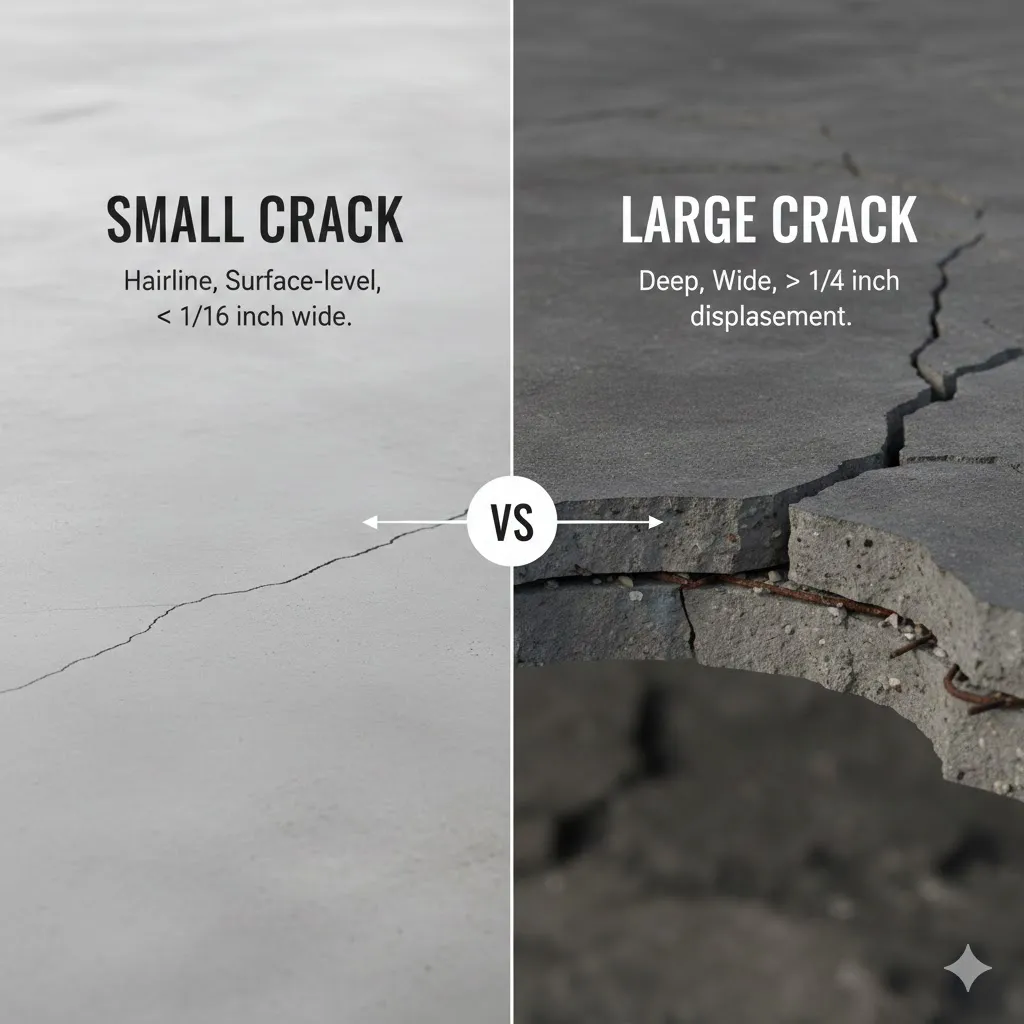

Signs of poor quality concrete include visible cracks, scaling, dusting, or reduced load‑bearing capacity. For DIY projects, following proper mix ratios and curing practices can help avoid these issues.

What Is Concrete Made Of in the USA?

In the United States, the standard concrete recipe is similar to the global one: Portland cement, water, sand, and gravel. However, there are some regional variations and sustainability trends worth noting:

- Fly ash and slag cement: These are industrial byproducts often used to replace a portion of Portland cement. They make concrete more eco‑friendly and durable.

- Recycled aggregates: Crushed concrete from demolished buildings is sometimes reused in new mixes.

- Admixtures for climate: In colder regions, admixtures are added to prevent freeze‑thaw damage.

American building codes also influence mix design, ensuring concrete meets specific strength and durability standards. So, while the basics remain the same, U.S. concrete often incorporates sustainable practices.

Types of Concrete

Concrete isn’t one‑size‑fits‑all. There are many types, each designed for specific purposes:

- Normal strength concrete: The everyday mix used for sidewalks, driveways, and small structures.

- High‑strength concrete: Designed for skyscrapers, bridges, and heavy‑load structures. It can withstand pressures above 6,000 psi.

- Lightweight concrete: Made with lightweight aggregates like expanded clay. Used for insulation and precast blocks.

- Stamped or decorative concrete: Colored, textured, or patterned for aesthetic appeal in patios and walkways.

- Ready‑mix concrete: Delivered in trucks, ready to pour. Convenient for large projects.

Each type has its own advantages. Choosing the right one depends on the project’s requirements.

Bonus Tip: Everyday Concrete Care

Concrete is tough, but it’s not invincible. Stains, cracks, and wear can affect its appearance and performance. For example, oil stains on driveways are a common headache. If you’re dealing with this issue, check out our guide on how to get oil out of concrete — it’s packed with practical solutions to keep your surfaces looking clean and fresh.

Conclusion

So, what is concrete made of? It’s more than just cement—it’s a blend of cement, water, aggregates, and sometimes admixtures. This simple recipe has built cities, bridges, and homes across the globe.

Understanding the difference between cement and concrete, recognizing the signs of poor quality, and knowing the types available can help beginners appreciate the science behind this everyday material.

Concrete may look ordinary, but it’s extraordinary in its ability to shape the world we live in. Next time you walk on a sidewalk or lean against a concrete wall, you’ll know exactly what’s holding it all together.

And remember, Concrete Verse is your go‑to digital resource for all things concrete. Whether you’re planning a DIY project or managing a larger build, our Concrete Calculator and Concrete Slab Calculator are here to make your work easier, faster, and more accurate.